Prototyping Division

The ideas of our customers take shape here

We start with a customer's idea, and make it real. We then take that real product and work to make it even better. Often, second or third prototypes are created in a process of refinement. It is our pleasure to work hard towards making our products better and better. We are standing by to take your order.

Primary Facilities

Work tables, molding machine, drill press, heat sealer, ultrasonic machine, industrial sewing machine, high-frequency welder, etc.

The Prototyping Process

1.Hearings

Intensive meetings are held closely following the order received by our sales staff to develop and share the product image.

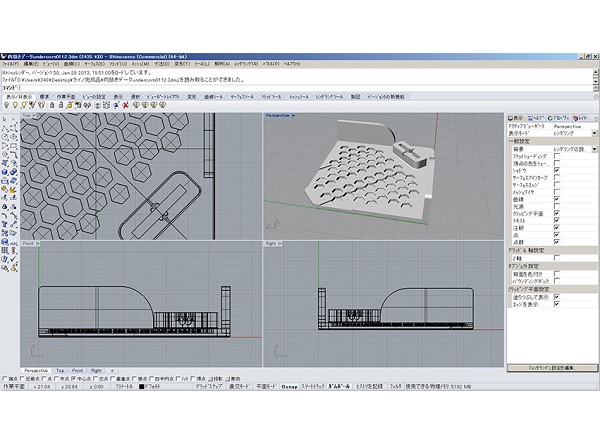

2.Design

Patterns are developed on paper. Data is also created which can be output using conventional and 3D printers.

3.Cutting

We carry out efficient cutting, applying our long years of experience and paying close attention to the dimensions and scale of the raw material so that little will be wasted in the manufacturing process.

4.Molding

We mainly use our large collection of proven molds, but if necessary we will build new molds for prototyping your product.

5.Welding

Welding can be used for most types of chemical products. We select the optimal welding process for the materials used to shape your product prototype.

6.Sewing

Sewing is used for finishing fiber-based materials such as cotton and nylon. A top-and-bottom feeding machine is used, which is optimal for chemical fiber products.

Product

Search